MMM (Multi-frequency Multimode Modulated) ultrasonic technology can be used to enhance the process of ultrasonic degassing of molten aluminium during casting. Best results were achieved with a combination of the special ultrasonics and low-frequency melt-stirring. The experimental results suggest that combining melt agitation and ultrasonic vibration it is possible to achieve almost the aluminium alloy’s theoretical density without increasing the processing time.

MMM (Multi-frequency Multimode Modulated) ultrasonic technology can be used to enhance the process of ultrasonic degassing of molten aluminium during casting. Best results were achieved with a combination of the special ultrasonics and low-frequency melt-stirring. The experimental results suggest that combining melt agitation and ultrasonic vibration it is possible to achieve almost the aluminium alloy’s theoretical density without increasing the processing time.

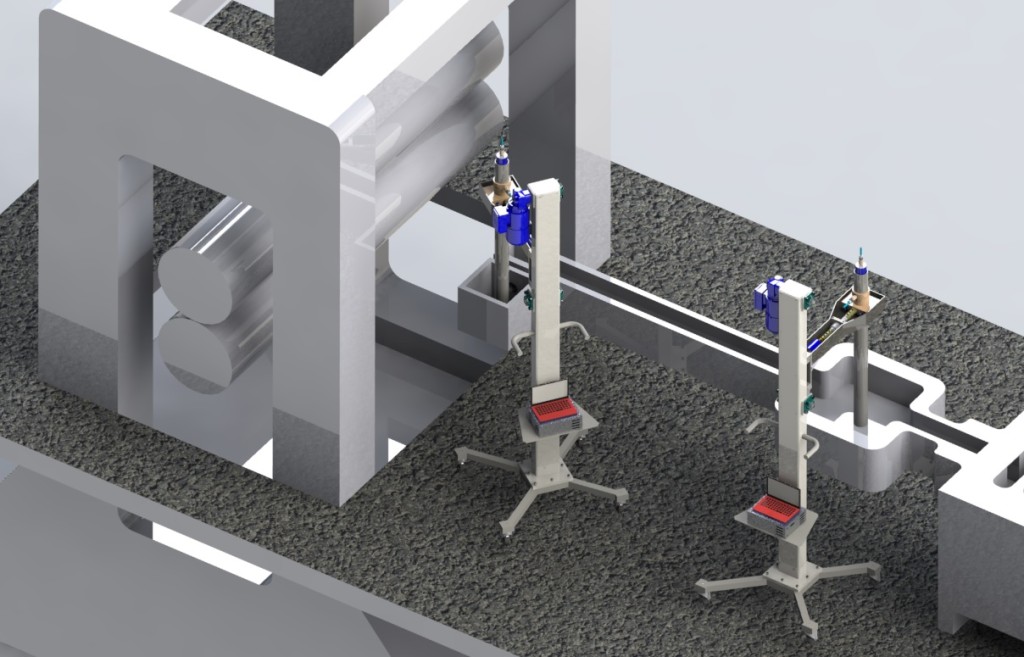

Images show (right) the ultrasonic equipment glowing at 1800°C after operation, and (diagram and below) the equipment suspended over the casting crucible.

a) Degassing apparatus including 1.furnace; 2.ultrasonic transducer; 3.low frequency mechanical vibrator; 4.radiator; 5.helicoids interface. b) Dislocation of the ultrasonic radiator under different mechanical vibration frequencies.

For more information on this series of experiments, please download the published paper: The influence of processing parameters on the ultrasonic degassing of molten AlSi9Cu3 aluminium alloy, by Hélder Puga, Joaquim Barbosa, E. Seabra, S. Ribeiro, M. Prokic

Ultrasonic processing of liquid metal in open channels before casting (pdf format, 287MB).

Various methods for introducing sonication in liquid aluminum and magnesium alloys (PDF, 873kB).

Various methods for introducing sonication in liquid aluminum and magnesium alloys (PDF, 873kB).

Brief review of other published literature

(Download papers and other information from our mastersonics.com website.)

Effect of Ultrasonic Processing of Molten Metal on Structure Formation and Improvement of Properties of High-Strength Al-Zn-Mg-Cu-Zr Alloys, by G. I. Eskin, G. S. Makarov and YU. P. Pimenov – Advanced Performance Materials, 2, 43-50 (1995)

This research into continuous casting aluminium with ultrasound has shown that the resulting material has an improved grain structure leading to increased ductility (up to 2 x) which assists subsequent hot-forming operations. In continuous casting of Al-Zn-Mg-Cu-Zr high-strength aluminium alloys, larger sizes can be cast without cracking.

Effect of power ultrasound on solidification of aluminium A356 alloy, by X. Jian, H. Xu, T. T Meek, Q. Han – Elsevier Materials Letters 59 (2005) 190-193

Various experiments show greatly refined and improved grain structure by applying ultrasonic energy to the melt.

Cavitation mechanism of ultrasonic melt degassing., by G. I. Eskin – Ultrasonics Sonochemistry 1995 vol. 2 no. 2

Discusses effects and mechanisms of ultrasonic degassing and concludes that cavitation is the key to hydrogen removal. Ultrasonic degassing of ingots and castings can reduce hydrogen content by more than 50%, leading to improved density and plasticity while retaining strength.

Advantages of MMM Ultrasonics

In all these technologies and applications, ultrasound above the threshold of acoustic cavitation can be introduced into the molten metal (eg. during the continuous casting process):

In all these technologies and applications, ultrasound above the threshold of acoustic cavitation can be introduced into the molten metal (eg. during the continuous casting process):

- Ultrasonic grain modification technology (microcrystallization).

- Ultrasonic filtering and refining of molten metal.

- Degassing and de-foaming of liquid metals using high intensity ultrasonics.

- Ultrasonic mixing and homogenizing of liquids is exceptionally efficient. Liquids and liquid metals that do not mix in normal conditions can also be mixed, homogenized and/or alloyed in high intensity ultrasonic reactors or in any casting process.

The advantages of MPI’s ultrasonic technology is that we can separate the ultrasonic transducers from the liquid metal using very long metal wave-guide rods, yet still introduce high ultrasonic power into the liquid metal. This has been impossible to achieve in traditional ultrasonic metal processing technologies.

There is a lot of literature regarding benefits of ultrasonic metallurgy, yet this technology is still not widely applied. The reasons are well known: Traditionally available ultrasonic equipment for liquid metals treatment is still not compatible with high-volume in-line metal processing, and the high temperature of liquid metals presents an enormous problem to continuous operation of ultrasonic transducers. MPI’s technology overcomes these problems.

There is a lot of literature regarding benefits of ultrasonic metallurgy, yet this technology is still not widely applied. The reasons are well known: Traditionally available ultrasonic equipment for liquid metals treatment is still not compatible with high-volume in-line metal processing, and the high temperature of liquid metals presents an enormous problem to continuous operation of ultrasonic transducers. MPI’s technology overcomes these problems.

All ultrasonic casting technologies are environmentally friendly, nonpolluting and purely based on the physical effects of Ultrasound.